Knitting a Business Together

October 24, 2023

Junction Fiber Mill founders blend quality and tradition with the “punk rock side of knitting” at their custom processing mill in Vermont.

Peggy Allen likes to knit. Amanda Kievet likes to knit. The two met over a skein of yarn Peggy was selling at the Norwich Farmers Market in 2018 and struck up a friendship. Amanda went back to the market to show Peggy the sweater she had made. That led to an invitation to sheep shearing day at Peggy’s Savage Hart Farm, which led to Amanda moving onto the farm for lambing season, which led to a road trip to a fiber mill in New York.

It was on that ride that the idea of starting Junction Fiber Mill began to take shape. Peggy, an entrepreneur with more than forty years of experience in the television industry, had “retired” to Vermont with her husband to raise sheep, but “is hard wired to work and not someone who wonders when she can put her feet up.” Amanda, a software developer approaching thirty, was looking for an adventure and a career more rooted in place. And, of course, they both loved to knit.

Realizing Opportunity

As the owner of a sheep farm and a fiber enthusiast, Peggy saw the need for a custom mill to process wool in Vermont. “There was a bottleneck,” she said, “a demand from smaller sheep farmers like me who wanted to have their wool milled into a high quality product. Driving to New York or Pennsylvania is a schlep.”

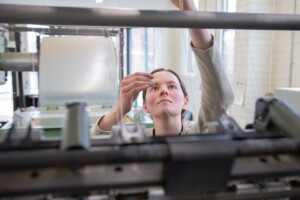

Peggy Allen and Amanda Kievet operate two businesses: One is custom processing, or processing wool as a service, for area sheep farms. The other is their Junction Fiber Mill label yarn, which they sell direct-to-consumer and wholesale through local yarn shops. Photo by Erica Houskeeper.

Just before COVID-19 hit in spring 2020, Peggy got word that a mill owner in Richmond, VT might be interested in selling his equipment. Peggy and Amanda drove up from White River Junction to take a look and fell in love. He had exactly the kind of milling equipment that Peggy had been driving up to seven hours to find.

“It felt like the right time to make the leap,” said Amanda, who had been traveling around Vermont visiting other mills and had come to the same conclusion as Peggy.

And so, they lept. After a lengthy search, they leased a building in White River Junction in 2021, which Peggy and her husband, Todd, later purchased to provide additional stability to the business. They moved the equipment from Richmond to their new factory space in February 2021 and, using their own wool, began to experiment.

Anastasia Spicer uses a spinner for plying yarn at Junction Fiber in White River Junction. Photo by Erica Houskeeper.

“We spent about two months getting to know the machines,” said Peggy. “When we hung our shingle out, we had business from day one. “There was a lot of demand.”

Junction Fiber Mill began as a service company, milling wool into usable fiber for local sheep farmers. The machines at the mill excel at processing wool with a high crimp, or waviness, from breeds such as Jacob, Corriedale, and Shetland. Lower crimp breeds like Border Leicester and Finn sometimes are blended with higher crimp breeds, while very low or no crimp breeds such as Gotland, Cotswold, and Teeswater are blended as a rule, as they cannot go through the machines on their own. Each job is kept completely separate to ensure that the roving or yarn returned to the farmer is made from the fleece of their own flock.

“The machinery is set up to do one small batch at a time,” said Amanda. “This is not a ‘set it and forget it’ operation.”

Within a few months, Peggy and Amanda saw another opportunity. “There are these very popular yarns made on the west coast,” said Amanda. “They’re variegated, meaning the color changes throughout the skein, but the wool is chemically treated to prevent felting or shrinking, and it loses some of the natural, beautiful characteristics of wool. We felt this challenge to make the same kind of yarn but with 100% natural, American wool.”

They began hand dyeing wool and experimenting with color. “We started in the garage,” said Peggy. “Good God, we were dying wool in a maple syrup pan! It was trial and error, but it was a lot of fun. The custom processing is all natural colors, so it was fun to be working with color.”

Today, they essentially have two businesses. The first is custom processing, or processing wool as a service, for area sheep farms. The second is their Junction Fiber Mill label yarn which they sell direct-to-consumer and wholesale through local yarn shops. “The yarn is what we’re known for nationwide,” said Amanda.

The Punk Rock Side of Knitting

For the first two years, the business grew through word of mouth, local fiber festivals, and regular open houses at the mill in White River Junction. The combination of their clear focus on producing high quality products and the bottleneck of demand allowed the business to begin generating revenue early on.

Junction Fiber Mill produces more than 80 different small batch, limited edition yarn colors along with more traditional colors, all from 100% natural, American wool. Photo by Erica Houskeeper.

As they began selling their yarn in local shops and reaching new customers around New England. Amanda suggested they start a Millcast–a video blog that would invite their customers into the mill and shed light on what a day in the life of a mill owner looks like. “We want people to connect with where their yarn comes from,” said Amanda. The idea was initially unpopular with Peggy, who only agreed when Amanda insisted that in all likelihood no one would watch. It caught on, however, and now has 40 episodes available on the website.

“There’s a kind of unintentional genius in our partnership,” said Amanda. “Peggy has been such an inspiration to so many people, starting this mill in her sixties. People are blown away. For me, I’m a new mom, I’m doing this on top of having a baby. I think people see us and they can relate, and they really want us to succeed.”

“Right now, the state of knitting is that there is a long history of older ladies knitting traditional garments for their families. That’s true to this day and remains the backbone. But there’s always been this alternative edge to it, people who see it as anarchist in a way. Right now that’s really surfacing, it’s younger people with tattoos and funky hair colors, and they’re knitting with neon colors.”

Junction Fiber Mill serves both, producing more than 80 different small batch, limited edition yarn colors such as “Starry Night,” “Forest Floor,” and “Pick Me Up, Buttercup,” along with more traditional colors, all from 100% natural, American wool.

“There are a lot of designers who are knitting fishnet sweaters, using glitter or superwashed yarn or characteristics that make it funky,” said Amanda. “We’re a really good balance of the two sides. We are using materials you can feel really good about, but we also have neons. What people come to us for is a nice, happy medium. You can knit a classic sweater that is passed down as an heirloom with our yarn and you can knit the latest funky styles.”

Finding Joy in Growth

With a loyal and growing customer base ranging from grandmothers to Gen Z, Peggy and Amanda began to explore wholesale markets.

In the winter of 2023, they applied to the New York Sheep and Wool Festival, which is notoriously difficult to get into. Not knowing if they would be accepted, they also applied to a big wholesale show in Chicago. They were invited to both.

With a gigantic opportunity ahead of them, Peggy and Amanda sought out support from the Vermont Sustainable Jobs Fund (VSJF) business coaching program. They met with VSJF Business Coach Carolyn Cooke, thanks to funding from the U.S. Small Business Administration’s Community Navigator Pilot Program (CNPP), to drill down on the true cost of their product–a first step to entering the wholesale market.

“You have to know, when you hold a skein, what does it actually cost to make that skein? The materials, the labor, the energy to run the mill,” said Peggy. “Knowing that gave us the confidence to get to a wholesale price that we could live with, and that local yarn shops could live with. We were able to feel good about that because of the work we did with Carolyn.”

Unsurprisingly, they came out of the shows with a “hefty load” of wholesale orders. It’s been a busy summer filling orders and making sure they have enough inventory for fiber festivals. As the business moves forward, they continue to work with Carolyn to develop a long term budget, marketing strategy, and human resources process.

“Getting ahead of those systems now will help them evaluate what it would mean to purchase a new piece of equipment or hire a manager,” said Carolyn, “which will give them more freedom in how they show up in the business.”

Amanda Kievet and Peggy Allen meet with business coach Carolyn Cooke, right, at Junction Fiber in White River Junction. The two sought out the VSJF Business Coaching program to drill down on the true cost of their product, which was a first step to entering the wholesale market. Photo by Erica Houskeeper.

And that freedom is important. For Amanda, having a baby gave her perspective. “At the beginning I had very tight reins on the business. When I was pregnant and realized I was going to have to leave for maternity, it actually led to some very healthy distance. I had to loosen up my reins. I did not get into this business to be solely focused on it. It’s part of a greater picture of my life.”

“Becoming a mom is the most life altering thing that can happen to a person,” said Peggy. “Oh, and by the way, we’re going to start this business and jump off a cliff while you’re pregnant. I’m not her mother, and I don’t play one on TV. I just feel peer-to-peer that how she’s running her life is fabulous. We’ve come so far and learned so much from each other.”

“I found a lot of joy working in the mill and not worrying about the business,” said Amanda, “so this transition of taking on the tasks of an owner instead of a worker has been painful at times. But I’m starting to find joy in it. I no longer feel guilty if I’m not on the floor because I see the value of the work we’re doing on the business.”

With a firm handle on the core of their business and a clear path ahead, Peggy and Amanda recently purchased another spinner from Italy that will more than double their capacity.

“It’s like the sun shines on this little business,” said Peggy. “It feels like a secret handshake. People are like, ‘I know you guys. I know your yarn.’ It’s this community we’re building with people. We’re authentic, we’re honest about the trials and tribulations, and we’re making a kick ass product. It’s extremely satisfying to see that resonate with people.”

About VSJF’s Business Management Coaching Program

The Vermont Sustainable Jobs Fund provides tailored, high-touch planning, coaching, and advising for business owners and their management teams to advance profitability, job creation, and sustainable job development. Click for more information about business management coaching. Funding support for our coaching program is provided by client fees, the SBA-Community Navigator Pilot Program, the Vermont Agency of Agriculture, Food and Markets, and Vermont Housing & Conservation Board’s Farm & Forest Viability Program.

Read More Stories Like This:

- Creating a Regional Food System, One Warehouse at a Time

- The Roots Farm Market Brings a New Approach to the Old General Store

- Babette’s Table: Using Projections to Grow with Intention

- Bobolink Yarns: Scaling Back to Find Success

- Hemp and Cannabis Pioneer, Scott Sparks, Navigates Legalization in Vermont

- Business Sense Training Series for Entrepreneurs and Small Business Owners

- Pioneers of African Cuisine, Global Village Foods Finds Community in Vermont