Next Generation Wood-Based Textiles Offer Northern Forest Market Development Opportunities

October 10, 2023

The potential for wood to replace plastic in woven and nonwoven textiles is progressing rapidly, offering new market development opportunities across the Northern Forest region, according to a new Market Opportunity Assessment commissioned by the Vermont Sustainable Jobs Fund (VSJF).

Forest to Fiber: Next-Generation Pathways for Vermont and Regional Leadership in Wood-Based Fiber and Textiles, explores some of the emerging technologies and markets that show promise for using pulp grade wood to replace oil-based plastics.

Lead Investigator Sarah Kelley with Common Threads Consulting presented the findings at the Vermont Forest Industry Summit September 14 at Bolton Valley Resort. The annual event brings together forest products stakeholders from across Vermont to network, learn and strengthen Vermont’s forest economy.

“In the last two years, fast-moving innovations, new companies, and policy developments in the wood-based fiber sector have fundamentally changed the landscape and allowed new pathways to take shape that offer promising alternative, non-chemical methods of producing a variety of textiles from wood,” said Kelley. Specifically, the research team ruled out the traditional dissolving pulp process as an option in favor of cutting edge nanocellulose technology.

The report includes an overview of the global and regional textiles industry, highlighting the industry’s evolution as well as current concerns about the sheer volume of textiles being produced and the waste being generated. It also provides data about various types of fiber, from animal and plant-based fibers to wood and man-made fibers. Interviews and research shed light on recent policy initiatives in Europe and elsewhere that are shaping global supply chains, opening potential opportunities for sustainable, next-generation wood-based textiles to be produced in Northern New England.

“Given that the global textiles market tops $1 trillion and that nearly two-thirds of all fibers we wear and use are made from oil, we felt compelled to investigate whether our region’s wood basket could contribute to a global solution that reduces our dependence on oil in favor of a sustainable and renewable resource for fiber,” said Christine McGowan, Director of VSJF’s Forest Products Development Program.

The report reviewed current conditions in the regional forest economy, noting that that both softwood and hardwood species can be used for wood- based fiber production, and that timber supply is not a restraint. According to statistics from the North East State Foresters (NEFA), annually, over 8.6 million cords (21.5 million tons) of excess timber can be found across New York, Vermont and New Hampshire and even if all of that were utilized, forest inventories would remain stable.

The report also noted that advanced research on wood-based textiles is being conducted at the University of Maine at Orono that can lend regional expertise to entrepreneurs and others looking to develop the technology in the region.

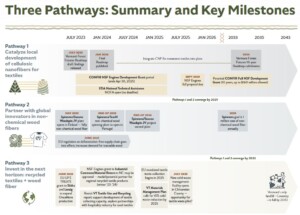

The report identifies three possible pathways for Vermont and the region to consider:

- catalyze local development of cellulosic nanofibers (CNF) from wood for textiles;

- partner with global innovators in non-chemical wood fibers; and/or

- invest in the next horizon: recycled textiles and wood fiber.

Recognizing that the global textiles industry is massive, “We propose that nonwovens and particularly biomedical textiles offer Vermont and the region options to gain an early adopter advantage by meeting the growing demand for specialized textiles that are designed from the start for circularity and full biodegradability,” said Kelley.

Addressing textile waste was also explored in the report, and the research team identified potential opportunities to develop a robust local textiles recycling industry that could combine recycled natural fibers with wood-based fibers to create new material that is fully biodegradable and compostable. While many textiles manufacturers boast using recycled plastics, these materials are still problematic because plastic remains in landfills for decades and as it degrades, particles make their way into water supplies.

“This is still at a very early stage, but we’re excited about the possibility to develop new markets for pulp grade wood from our region. The decline in pulp and paper mills in recent years has caused an alarming contraction of forest products businesses. Without these businesses, the regional forest products supply chain begins to break down, as does our ability to sustainably manage our forests and keep them resilient,” said McGowan.

The Vermont Sustainable Jobs Fund produced the report with funding support from the U.S. Department of Commerce Economic Development Administration, U.S. Endowment for Forestry and Communities, the Northern Forest Center, and the Vermont Housing and Conservation Board.

Click to Access the Forest to Fiber Report

About the Vermont Forest Products Program at VSJF

Vermont’s forest economy contributes more than $2 billion in direct economic output and provides more than 13,000 jobs in forestry, logging, processing, specialty woodworking, construction, wood heating, maple production, and forest-based recreation. The Forest Products Program at the Vermont Sustainable Jobs Fund (VSJF) creates space for strong relationships and collaboration throughout the industry and promotes the development of new and existing markets for Vermont wood products. Committed to nurturing the sustainable development of Vermont’s economy, VSJF provides business assistance, network development, strategic planning, and value chain facilitation in agriculture and food system, forest products, waste management, renewable energy, and environmental technology sectors. Learn more at www.vsjf.org.